- +86 18866611795

- [email protected]

- Address:Renmei Road, Yanzhou District, Jining City, China

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

This equipment is a 47.6-ton ultra-large hydraulic excavator, equipped with a Cummins SQM11 engine (250kW), a 2.2~2.5m³ bucket, a maximum digging depth of 7.8 meters, and a traction force of 330kN. Heavy-duty power chain: 11L displacement engine + high-pressure hydraulic system, suitable for high-intensity operations. All-terrain adaptability: 35° climbing ability + low ground pressure design, competent for complex working conditions such as mines and wetlands. High reliability: Strengthened frame and intelligent monitoring system to ensure long-term stable operation. It is the preferred heavy equipment for mines, ports and large-scale infrastructure projects.

![]() Whatsapp : +8618866611795

Whatsapp : +8618866611795

![]() Email : [email protected]

Email : [email protected]

| Engine | |

|---|---|

| Engine model | Cummins SQM11 |

| Rated power (kw/rpm) | 250/2000 |

| Displacement (L) | 11 |

| Type | 6 cylinders, in-line, supercharged, intercooled |

| Number of cylinders × cylinder diameter × stroke (mm) | 6×125×150 |

| Operating weight and ground pressure ratio | |

| Operating weight (Kg) | 47600 |

| Ground pressure ratio (Kpa) | 81.9 |

| Travel system | |

| Travel motor | Axial variable piston motor |

| Number of track shoes | 2×50 |

| Travel speed (Km/h) | 3.2/5.3 |

| Traction force (KN) | 330 |

| Gradability | 70%(35°) |

| Number of supporting rollers | 2×9 |

| Number of sprocket wheels | 2×2 |

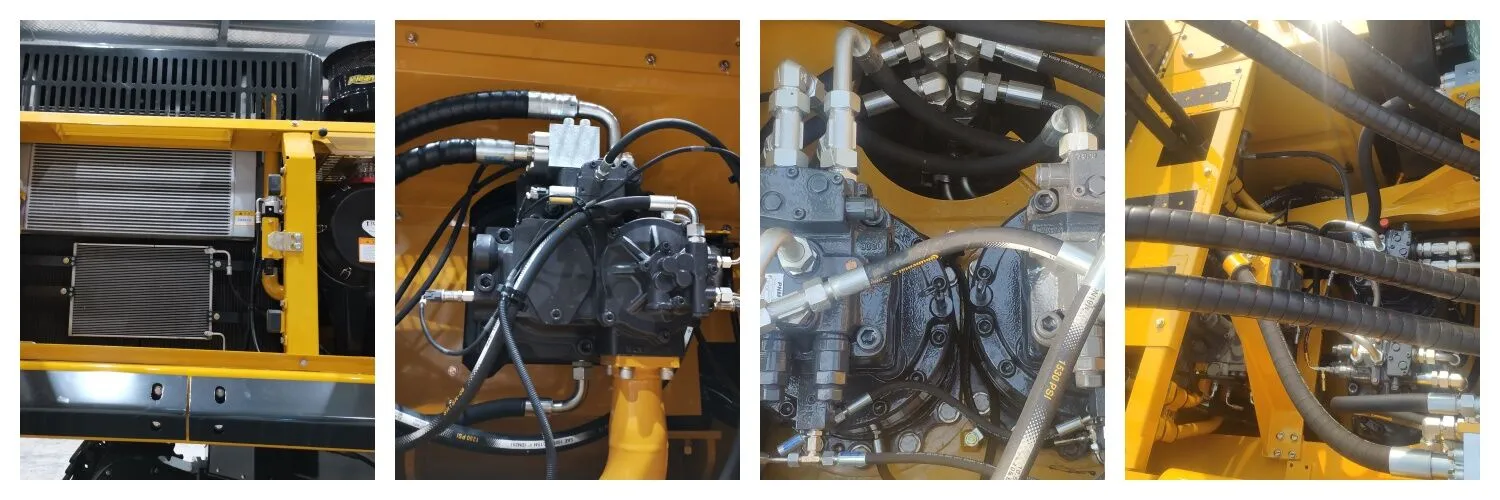

| Hydraulic system | |

| Hydraulic pump type | 2 variable piston pumps + 1 gear pump |

| Main pump displacement (mL/r) | 2×360+30 |

| Travel circuit pressure (Mpa) | 31.4 |

| Slewing circuit pressure (Mpa) | 28.4 |

| Control circuit pressure (Mpa) | 3.9 |

| Slewing system | |

| Slewing speed (r/min) | 9.3 |

| Brake type | Pressure release mechanical brake |

| Bucket | |

| Bucket capacity (m³) | 2.2~2.5 |

| Bucket width (mm) | 1530~1706 |

| Maximum digging depth (mm) | 7800 |

| Digging force | |

| Arm digging force (KN) | 236 |

| Bucket digging force (KN) | 290 |

| Fluid capacity | |

| Fuel tank capacity (L) | 650 |

| Cooling system (L) | 26 |

| Engine oil volume (L) | 37.8 |

| Hydraulic oil tank filling volume (L) | 350 |

| Hydraulic oil tank system capacity (L) | 406 |

Engine:

The Cummins QSM11 engine is reliable, efficient, low fuel consumption, meets Euro 3 emission standards, has excellent performance, is energy-saving and environmentally friendly, and is easy to maintain.

Hydraulic system:

Original imported hydraulic components, electrically controlled dual pump full power crossover+negative flow control system, hydraulic pilot proportional control, stable and reliable quality, high work efficiency, energy-saving and consumption reduction, and large excavation force;

Equipped with electrical control system:

Dot matrix multifunctional large screen color LCD display, capable of real-time monitoring of machine operation status, with fault self diagnosis and recording functions, electronic throttle control, always considering fuel economy, ensuring maximum efficiency of the entire machine when operating in various work sites. Provide multiple operating modes for users to choose from, meeting different working conditions;

Enhanced working device:

The strengthened design of the working device is more suitable for harsh working environments such as mines and quarries. The rotary platform adopts a new type of high-strength and high stability, and the frame edge beam edge plate angle steel is strengthened. The key parts of the chassis are increased in strength, improving their service life. It has a wide rail gauge and a long track grounding length.

This 47.6-ton large hydraulic excavator is designed for mining, large earthwork projects, port loading and unloading, and major infrastructure construction. In mining scenarios, its 290kN bucket digging force and 11L large-displacement engine can efficiently crush hard rocks; in earthwork projects, the maximum digging depth of 7.8 meters and the 2.5m³ large-capacity bucket meet the needs of deep foundation pits and high slope operations; the dual-speed travel system and 35° climbing ability ensure that the equipment can operate stably in complex terrains such as muddy and steep slopes. In addition, the 350L hydraulic oil tank and 650L fuel tank support long-term continuous operation, making it a high-productivity core equipment for large-scale engineering projects.

We are committed to using industry-leading components to ensure that every piece of equipment meets the highest standards

With years of experience, we have amassed a deep technical foundation and expertise, enabling us to better meet our customers' needs.

A well-developed global spare parts supply network ensures fast delivery of common spare parts and reduces equipment downtime.

We can provide our customers with comprehensive customization services, customized according to their specific needs, and on-site technology.

It can be conducted at the customer's site or at the company's training center to provide excavator operator training to customers.

Strict quality control, such as finished product inspection and on-site material inspection, ensures reliable product quality.

Focusing on R & D innovation, the team members have extensive industry experience and cutting-edge technical knowledge.

Do you want your Icon box in a listing method and filled with wonderful colouring Icon? Then you should give a try on this Icon box style!

We are committed to using industry-leading components to ensure that every piece of equipment meets the highest standards

Don’t miss our products of excellent quality! Contact us now!

Please send your requirements below, and we will get back to you soon. Thank you!